LIFE Multi-AD 4 AgroSMEs: High performance multiphase anaerobic reactor for agroindustrial wastewater treatment

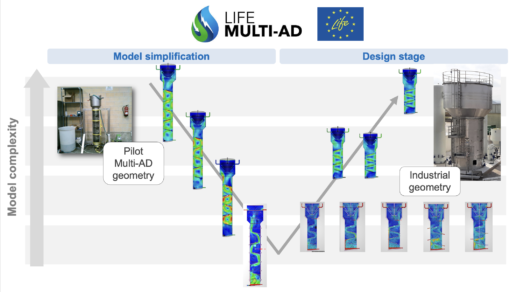

UPSCALING – COMPUTATIONAL SIMULATION SUPPORT ON INDUSTRIAL SCALE DESIGN

Multi-AD 4 AgroSMEs Project was born from the anaerobic multiphase reactor patented by AEMA. This technology was experimentally tested at a 0.1 m3pilot scale prototype giving promising results regarding efficiency, environmental impact and costs. One of the objectives of the project is the development of a new design based on AEMAs prototype and adequate for its operation at the industrial scale. This upscaling process was supported by Computational Fluid Dynamic (CFD) modeling, a technique that provides information about the performance of a new design prior to its construction.

Computational Fluid Dynamics (CFD) makes use of numerical methods and algorithms to solve problems regarding fluid mechanics that is the physics branch studying the liquid and gaseous movement and the forces causing them. ITAINNOVA has wide experience on CFD modeling and simulation and its application on industry for virtual sensoring, model based control, process optimization and product design.

Anaerobic reactors for wastewater hydrolysis, acidogenesis, acetogenesis and methanogenesis. The organic matter contained in the water (liquid) is put into contact with the biomass (solid particles) to degrade it and generate biogas (gas). An adequate mixing of liquid and solid particles is essential to achieve high reaction yields. Multi-AD reactor takes advantage of the turbulence created by geometry to provide mixing avoiding the use of mechanical stirring.

The upscaling of the process made it necessary the modification of the pilot plant design to adapt it to industrial plants characteristic requirements. Structural limitations, safety and economical efficiency goal were the main challenges tackled in the reactor redesign process. It was accomplished in three steps: i) the acquisition of knowledge about pilot plant performance (specially the mixing level), ii) the proposal of design modifications meeting the industrial size requirements and iii) the evaluation of the new design mixing level. CFD models and simulations were key tools in all these steps.

A complete Multi-AD reactor model comprises a multiphase (solid particles, liquid and gas) model, a turbulence model, and solving biochemical reactions together with energy and species transport equations. This complexity makes the model computationally demanding and, thus, the simulation becomes time consuming. During the upscaling, several geometries had to be tested. This kind of complex model was therefore incompatible with a quick design procedure.

A methodology was developed to address this issue. Different models were implemented to adapt their features, mainly accuracy and computation demand, to the agility required in each part of the process. The model was modified into three levels of simplification concerning the mesh, the number of phases involved, and the phenomena studied. The complex pilot plant model was used to determine the accuracy of each simplification and the parameters indicating good mixing and adequate performance.

The simplest model permitted fast geometry modification and real time simulation. It was used in an initial screening of multiple different designs. Results provided no accurate values but trends indicating the most promising geometries. This selection was simulated and analyzed using the subsequent level of simplification models to obtain quantitative results and determine the most adequate design.

The selected reactor represents a balance among performance, construction viability and costs. It is already installed in the demonstration plant and will be tested within the Multi-AD 4 AgroSMEs project during the next months.

THIRD GENERAL ASSEMBLY: THE PARTNERS OF THE LIFE MULTI-AD PROJECT PRESENT THEIR TECHNICAL ADVANCES TO THE NEEMO MONITORING TEAM.

The partners of the European project LIFE Multi-AD 4 AgroSMEs (LIFE17 ENV / ES / 000331), made up of AEMA (Water, Energy and Environment Servicios Integrales SLU), I&S (Institutions & Strategies), ITAINNOVA (Instituto Tecnológico de Aragón), SIS (Societatea de Inginerie Sisteme SA) and EGA(Energygreen Gas Almazán SL), have held a new working meeting to show the progress and results of this initiative. The meeting was attended by the Executive Agency for SMEs (European Commission) through a representative of NEEMO and project monitor, Mariona Salvatella.

During the meeting, which was held online, the results of the different actions carried out during the last nine months were presented. In addition, it has been used to make a virtual visit to the demonstration prototype, which is in the construction phase. During the visit, the progress in the assembly of the different elements that make up the demonstration unit was shown, as well as the current WWTP, based on an aerobic process, which will be used as a base scenario to evaluate the technical, economic and environmental feasibility of the LIFE Multi-AD technology solution.

At large ranges, the LIFE Multi-AD 4 AgroSMEs project aims to design and industrialize a high-performance multi-stage anaerobic reactor, adapted to treat wastewater generated in small and medium-sized enterprises (SMEs) of the agri-food industry (F&D). This project, which has a budget of € 2,177,143.00, is 60% co-financed by the LIFE program of the European Commission. The LIFE program is the EU funding instrument for the environment and climate action created in 1992.

LIFE MULTI-AD 4 AGROSMES PROJECT PARTICIPATED IN THE WCCM-ECCOMAS CONGRESS 2020

Instituto Tecnológico de Aragón (ITAINNOVA) presented part of the work carried out within LIFE Multi-AD project in the WCCM-ECCOMAS congress 2020, which took place in digital version from January 11 to 15, 2021.

Cristina Bengoechea Cuadrado, researcher in Instituto Tecnológico de Aragón (ITAINNOVA), presented the LIFE Multi-AD Project in the joint 14th World Congress in Computational Mechanics and ECCOMAS Congress 2020, virtually held last 11–15 January 2021. The congress was one of the largest international applied mathematics and computational mechanics events, in which participated more than 3000 people from different sectors, industry, academia and government institutions.

In the talk it was presented a multifidelity simulation methodology to facilitate and speed up the design stage of wastewater treatment reactors, developed by ITAINNOVA within the EU-funded LIFE Multi-AD project. The talk was included in the minisymposium “Efficient Methods for Multi-Disciplinary Optimisation, Probabilistic Design and Optimisation under Uncertainty”.

LIFE MULTI-AD CONTRIBUTES TO THE UNITED NATIONS SUSTAINABLE DEVELOPMENT GOALS

On September 25, 2015, the 193 countries that make up the United Nations committed to the SUSTAINABLE DEVELOPMENT GOALS (SDGs) and their fulfillment by 2030.

The goals pursue equality among people, protect the planet and ensure prosperity as part of a new sustainable development agenda. A new global social contract that leaves no one behind.

The 2030 Agenda for Sustainable Development proposes 17 Sustainable Development Goals with 169 goals of an integrated and indivisible nature that cover the economic, social and environmental spheres.

The development and industrialization of the innovative technological solution LIFE Multi-AD, capable of treating and recovering the wastewater of agro-food SMEs producing biogas, will directly contribute to the achievement of the SDGs:

06. Ensure the availability and sustainable management of water and sanitation for all. The LIFE Multi-AD technological solution will treat wastewater through the application of an anaerobic system, a process considered one of the most sustainable alternatives in wastewater treatment.

07. Ensure access to affordable, reliable, sustainable and modern energy for all. The anaerobic LIFE Multi-AD process will enhance the organic load of the wastewater by producing biogas, which will be used as a renewable energy source, reducing the Carbon Footprint.

08. Promote sustained, inclusive and sustainable economic growth, full and productive employment, and decent work for all. The innovative LIFE Multi-AD solution is being developed by a European consortium of 5 companies from Spain, Romania and France.

09. Develop resilient infrastructure, promote inclusive and sustainable industrialization, and foster innovation. LIFE Multi-AD will industrialize a high performance high performance multi-stage anaerobic reactor, based on the AEMA patent (ES-2541078), which will be fully automated.

11. Make cities and human settlements inclusive, safe, resilient and sustainable. The LIFE Multi-AD solution, with a treatment capacity of up to 120 m3 / day, will be demonstrated its technical, economic and environmental viability in a DOCa Rioja winery (Spain).

12. Guarantee sustainable consumption and production patterns. LIFE Multi-AD will contribute to the development of strategies on efficiency in the use of resources based on the framework of production models under Circular Economy.

PROJET LIFE MULTI-AD: NETWORKING ACTIVITY

Within the framework of the networking activities of the LIFE Multi-AD AgroSMEs, project, Jose B. Carbajo attended the final session of the iCirBus-4Industries as its representative, which took place on December 4 in virtual mode.

LIFE iCirBus-4Industries puts into practice the concept of circular economy through actions focused on the cascading use of waste from regional biomass energy and water treatment industries, to become new validated green products for materials industries construction and fertilizers.

The day, in addition to being a showcase to show the main results achieved by iCirBus-4Industries, served as a meeting forum between different European consortia. Especially interesting has been the networking carried out with projects based on anaerobic technologies such as LIFE Anadry or those whose objective is the recovery of waste from the agri-food industry (e.g., LIFE Brewery).

There is no doubt that thanks to the support of the European Commission through the LIFE program there is a wide network of projects developing in favor of the environment and the circular economy.

ANAEROBIC SYSTEMS: A STEP FORWARD IN PROGRESS TOWARDS A SUSTAINABLE WASTEWATER TREATMENT

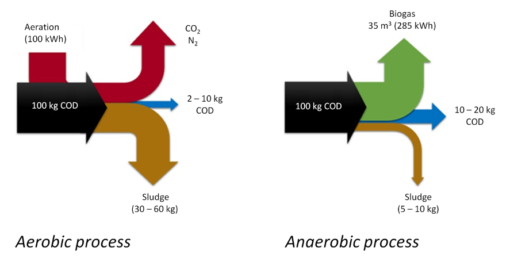

Anaerobic process is considered one of the most sustainable alternatives for wastewater treatment. Low energy use, low sludge production, small reactor surface area, low consumption of nutrients compounds and reduced operating expenses are some of the advantages that anaerobic process has over conventional aerobic process based on activated sludge.

The activated sludge process is a type of wastewater treatment process for treating wastewaters using aeration and a biological floc. This community of microorganism is capable to oxidize organic pollutant into carbon dioxide and water.. Aerobic process implies high energy requirement, 0.7 – 1 kWh/kg COD, and low organic load rates, 0.5-2.0 kg COD/m3·d.

On the other hand, in anaerobic process, anaerobic microorganisms (specific to oxygen-free conditions) are selected for their ability to degrade organic matter present in wastewater. More precisely, organic pollutants are converted into biogas (methane + carbon dioxide) and a small amount of biosolids. In this wastewater systems, energy used could be reduced up to 10 times in comparation with aerobic process (0.07 – 1.0 kWh/k DQO) as aeration is not required. Moreover, biogas, methane-rich gas, may be used as renewable energy source, which reduces the energy demand of wastewater process.

Comparative balance of aerobic and anaerobic wastewater treatment processes

It is important to highlight that the organic load rates used in anaerobic process can reach up to 25 kg COD/m3·d, which allows the treatment of biodegradable wastewater with a high COD concentration, as well as reducing the reactor surface area.

Finally, anaerobic process also has the advantage of being able to value the granular biomass produced in the market, as sowing in reactors for the start-up of other plants, thus significantly reducing the cost associated with sludge treatment.

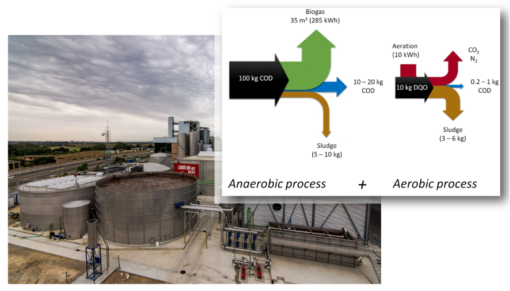

Synergistic binomial of biological processes: anaerobic + aerobic

Although anaerobic systems may be capable of treating wastewater with higher organic loads than aerobic ones, they have a limited capacity both for the removal of nutrients (ie, nitrogen and phosphorus) and for the refining of organic matter in the effluent (ie, COD removal yields <90%).

It is therefore evident that an effective and efficient treatment of industrial wastewater with a high biodegradable organic load with discharge into the water bodies should be carried out through the synergistic combination of the two biological processes:

- Anaerobic, as a roughing treatment and recovery of organic matter in an energy source such as biogas.

- Aerobic, as a process for polishing the COD and removing the nutrients to fulfillthe limits established in the wastewater discharge authorization.

Balance of the mixed wastewater treatment system: anaerobic + aerobic. Photo La Zaragozana (Ambar), success story of EDARi built and operated by AEMA

A case of success in the brewing sector for the treatment of wastewater using mixed anaerobic + aerobic technology is the Spanish brewery located in Zaragoza, La Zaragozana (Ambar). The WWTP of the aforementioned beverage company, built and operated by AEMA, is capable of treating 3,270 m3 of wastewater daily, producing about 5,000 m3 of biogas. The biogas is energetically valued in the facility itself, taking advantage of its calorific power, which contributes positively to the reduction of the brewery’s carbon footprint.

LIFE Multi-AD technology solution

The LIFE Multi-AD project is developing and industrializing an innovative technological solution based on the design of a high performance multi-stage anaerobic reactor patented by AEMA. The demonstration project will help as a technological lever to advance the synergistic combination of anaerobic and aerobic purification systems.

The LIFE Multi-AD project will reduce the environmental impact of food SMEs as well as the operating expenses derived from treatment. The technological solution will reduce the organic load of the wastewater, producing biogas, which will be used as a source of renewable energy, thus saving natural resources and reducing the carbon footprint.

The LIFE Multi-AD project is supported 60% by the LIFE + ENVIRONMENT program of the European Commission and is coordinated by AEMA, as an expert in industrial wastewater treatment technologies. Also involved in the consortium ITAINNOVA, technological center of reference in technological innovation, SIS, company that provides solutions in the field of industrial automation, EGA, specialist in the management and recovery of organic waste through anaerobic digestion and I&S, consultant and advisor in communication of European and international projects..