6th Newsletter LIFE Multi-AD 4 AgroSMEs.

LIFE Multi-AD 4 AgroSMEs: High performance multiphase anaerobic reactor for agroindustrial wastewater treatment

News LIFE Multi-AD 4 AgroSMEs.

GOICOECHEA OBTAINS THE DEGREE IN CHEMICAL ENGINEERING BY DEFENDING ITS FDP WITHIN THE FRAMEWORK OF THE LIFE MULTI-AD PROJECT

Blanca Goicoechea, technician of the R&D department of AEMA, has defended her Final Degree Project (FDP) entitled » Tratamiento de aguas residuales de una industria de conservas vegetales mediante reactor anaerobio multi-etapa de alto rendimiento (Multi-AD) ».

The research work, framed within Activity 5 of the LIFE Multi-AD 4 AgroSMEs project (LIFE17 ENV/ES/000331), has been carried out at the AEMA facilities under the direction of Jose B. Carbajo. The FDP, rated with a grade of 9.8, has allowed Goicoechea to achieve a degree in Chemical Engineering from the University of Zaragoza.

Piloting the Multi-AD technological solution

The research work evaluates, on a pilot scale and on a continuous mode, the technical and economic feasibility of the high-performance multi-stage reactor (Multi-AD) to treat wastewater generated by a vegetable canning company. The results show that the Multi-AD technological solution is capable of effectively treating the aforementioned industrial discharges, reaching organic load rates of 20 kg COD/m3·day with COD removal yields greater than 90%.

The design of the anaerobic reactor, composed of four independent chambers, ensures that the process of removing organic matter takes place in a staggered manner. This fact allows that, for the same degradation rates, Multi-AD technology needs a smaller volume than a conventional UASB reactor.

In addition, as a result of the anaerobic digestion process, the Multi-AD technological package is able to valorize organic matter by producing biogas. Biogas with a methane content higher than 80% could be used as renewable energy both in the water treatment process itself and in any industrial use in the agri-food company itself.

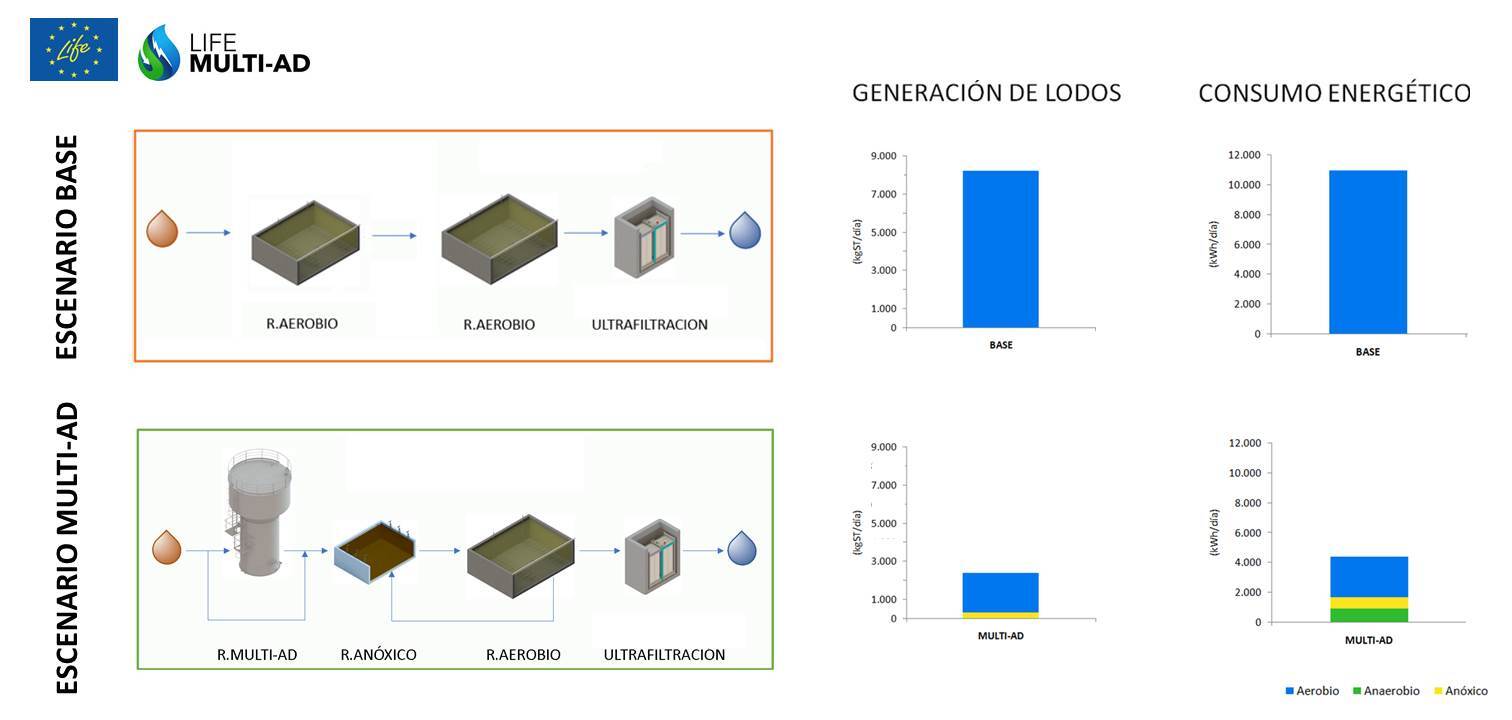

Industrial-scale scenario study

The theoretical comparison of scenarios (i.e., aerobic base-process scenario and Multi-AD scenario), shows that the integration of the anaerobic system could reduce the energy consumption of the EDARi, by 60%, as well as reducing the sludge productions to be managed by more than 70%.

The installation of the Multi-AD technological package in the treatment plant under study requires the replacement of one of the aerobic reactors with an anoxic one. The integration of an anoxic-aerobic process achieves the elimination of nitrogen to concentrations that allow compliance with the limits of discharge to channel.

Finally, it is important to emphasize that the results achieved in the aforementioned work have shown that Multi-AD technology contributes to Sustainable Development Goals 6 and 7, clean water and sanitation, and affordable and clean energy and their targets b and a, respectively.

…

The 15th International Bioenergy Congress

The 15th International Bioenergy Congress (15 Congreso Internacional de Bioenergía) was held 5-6th October in Valladolid (Spain). It was organized by AVEBIOM, the Spanish Association of Biomass, and AEBIG, the Spanish Association of Biogas. 583 participants had the chance to attend more than sixty oral and poster presentations addressing the challenges and opportunities of bioenergy, and the research and innovation advances on this technology. This Congress was scheduled to coincide with the II Renewable Gas Trade Fair (II Salón del Gas Renovable), where more than 2000 professionals visited more than 100 stands from 12 different countries.

ITAINNOVA presented the work developed within the LIFE Multi-AD 4AgroSMEs project in the Congress. The poster Digital Twin for Design and Upscaling of Anaerobic Reactor summarized the project challenges and explained how Digital Twin technology supported the reactor redesign process required for its industrialization. This contribution was focused on the computational fluid dynamic models and the methodology developed by ITAINNOVA during the project.

Póster ITAINNOVA_Congreso Bioenergía 2022

Control solution for High performance multiphase anaerobic reactor for agroindustrial wastewater treatment

The LIFE Multi-AD 4 AgroSMEs project aims to develop a high-performance multiphase anaerobic reactor for its industrialization, which generates methane-rich biogas, specially designed for wastewater treatment generated in small and medium enterprises in the food and beverage industry.

The successful operation of an anaerobic reactor depends on keeping the environmental factors close to the comfort range of the microorganisms. For example, changes in temperature, pH or organic matter concentration of wastewater can cause biogas production to stop. Thus, keymportant parameters in this process are: temperature, pH, redox potential, organic loading rate, solid and nutrient concentration.

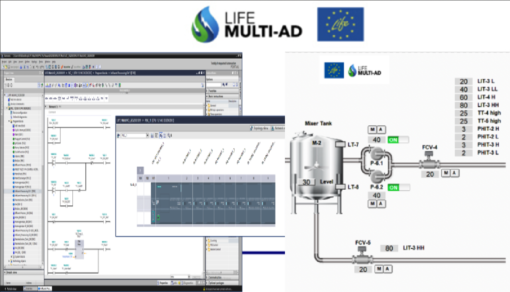

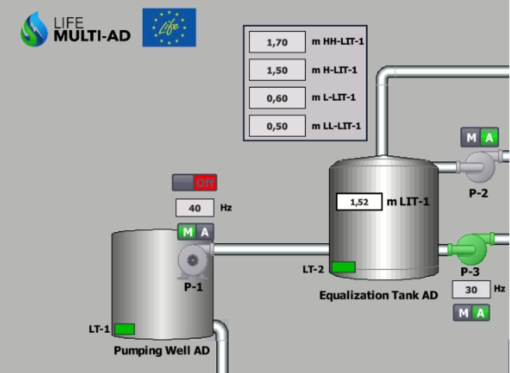

One of the specific objetives of the LIFE Multi-AD project is to develop, optimize and automate the control system to maximize the stability of the anaerobic process and make it robust to changes in wastewater composition or operating conditions. The control system will automatically adjust the controllable output variables (temperature, pH, total suspended solids (TSS), chemical oxygen demand (COD), wastewater flow), using algorithms and logic functions. The main functions of the automation system are: monitoring the level, COD, TSS, temperature and pH in the tanks, displaying the parameters and alerting the operator when the parameters of the normal operating limits are exceeded.

The automation system was developed based on an innovative technological scheme, which includes details on how wastewater from the beverage industry is supplied to the wastewater treatment plant to power the Multi-AD reactor and how the resulting biogas is processed to allow further capitalization.

The LIFE Multi-AD project has successfully completed the development stage of the advanced based control system for automating the control of process parameters. At this stage, based on the results of the previous actions, a 1: 1 demonstration work unit of the Multi-AD reactor on an industrial scale of 100 m3 was built to validate its performance.

SIS part of the project was the automation of the whole process. This journey has started at the design phase, when we analyzed the process and created the best configuration for the automation cabinet of this application. Further, we used TIA Portal V16 to program the logic, using a “Cause-effect” approach, thus interconnecting the whole station and making the operation as safe as possible. Simulation and testing procedures were done by using the extension PLCSim, to ensure that we deliver a logic that works like a charm.

Automation means nothing if you cannot control and monitor it, so we developed two solutions for this application.

The first one is a physical HMI interface, placed on the automation cabinet, created with the help of WinCC Siemens software, it is a graphical representation of the whole station, making it easy for an operator to change set-points, activate and deactivate pumps, monitor values and much more.

The operator interface consists of ten screens: the main screen, four detail screens, the pump screen, the electrical screen, the timer screen and the alarm screen. The main screen shows the complete scheme of the system and allows navigation through the buttons to the other screens. The detail screens aim to track each area of the system with all the elements and parameters associated with them. In the limits screen are visible all the extreme values of the system on each element with the possibility of adjustment by the operator. The list of system alarm messages is available in the alarm screen.

The realized Multi-AD demo unit was installed and has been tested on the system with the possibility of redesign, thus being able to optimize its model and operational parameters. Finally, the fact that the Multi-AD reactor is fully automated with advanced control is part of the Industry 4.0 concept, as our device uses a large number of sensors and implements intelligent computing machines, among other technologies.

This LIFE Multi-AD project offers an innovative technological solution, ready to be adopted by small and medium enterprises in the food and beverage industry.

LIFE Multi-AD and WalNUT seek synergies to advance the recovery of resources present in wastewater

On 12 May, LIFE Multi-AD continued to make progress in building collaborative networks through a meeting with CETAQUA and the WalNUT – Closing Waste water cycles for nutrient recovery project.

The meeting showed the set of technological packages under development by both European initiatives, which have as a common denominator to advance the sustainable use of resources present in wastewater.

Specifically, LIFE Multi-AD, through anaerobic processes, is carrying out an effective and efficient recovery of the organic matter present in industrial effluents through the production of biogas, While, WalNUT is working on the recovery of nutrients present in wastewater for the production of biofertilizers.

It is therefore important to note that both LIFE Multi-AD and WalNUT are developing synergistic technology solutions. In fact, its integration into future wastewater treatment plants would allow the agro-food industry to advance strategies on resource efficiency within the framework of production models under Circular Economy.

LIFE MULTI-AD continues to build a network with technologies synergistic to the anaerobic water treatment process.

Within the framework of the networking activities of the LIFE Multi-AD AgroSMEs project, Jose B. Carbajo attended on November 30 the Technical Seminar organised by LIFE ENRICH: Recovery of nutrients from wastewater to produce agricultural fertilisers.

LIFE ENRICH aims to contribute to the circular economy through the recovery of nutrients from wastewater and their use as fertiliser for crops. To do this, it has developed a technological solution based on an innovative treatment train that integrates cutting-edge technologies capable of allowing efficient recovery of nitrogen and phosphorus contained in wastewater in the form of ammonium and struvite salts.

Through this meeting, LIFE Multi-AD AgroSMEs continues to build a network with synergistic technological solutions to the anaerobic process that it is developing through the High Performance Multistage Anaerobic Reactor for Wastewater Treatment of Industrialists in the Agrifood Sector.

Wastewater, key to the future

Wastewater is a valuable resource that must be returned to the receiving environment in adequate quality, especially in areas under severe water stress.

Global warming, whose intensity and economic and environmental impact has increased significantly over the last thirty years, is restricting the availability of freshwater for urban development and agriculture. Thus, the future of the planet depends on sustainable and efficient water management.

According to the UNESCO World Water Assessment Programme report, 80% of the planet’s wastewater returns to the ecosystem with inadequate quality and cannot be used as a vital resource. In this sense, organic matter and nutrients can have a negative impact on both the environment and human beings.

Untreated wastewater reduces the quality of natural freshwater sources, which in many developing countries is a major problem for people’s health.

Investing in efficient wastewater treatment technologies and other sanitation infrastructure is crucial to achieving public health benefits, improving the environment and quality of life. Safely managed water, sanitation and hygiene services are an essential part of preventing disease and protecting human health during infectious disease outbreaks.

Moreover, wastewater treatment offers a dual value proposition, as in addition to the environmental and health benefits, it can generate economic income through reuse in different sectors.

Along these lines, the resources obtained from wastewater, such as nutrients and biogas, can be used as fertilisers and energy sources, while the additional income generated by this process can help cover the operational and maintenance costs of wastewater treatment companies.

By taking care of water, we also preserve this resource for the future, by protecting the environment and, above all, by making economic use of our own waste, which represents a great opportunity for both nature and development.

About the project

The main objective of the LIFE Multi-AD 4 AgroSMEsproject is to develop and industrialize an innovative fully automated system for the treatment of wastewater generated by small and medium-sized companies from the Food & Drink (F&D) sector. This technology is based on the design of high-performance anaerobic multiphase reactor patented by AEMA and its production will be personalized according to the specific needs of each client.

|