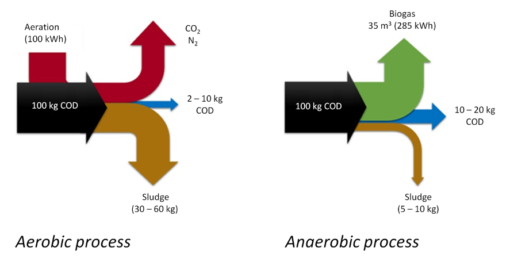

Anaerobic process is considered one of the most sustainable alternatives for wastewater treatment. Low energy use, low sludge production, small reactor surface area, low consumption of nutrients compounds and reduced operating expenses are some of the advantages that anaerobic process has over conventional aerobic process based on activated sludge.

The activated sludge process is a type of wastewater treatment process for treating wastewaters using aeration and a biological floc. This community of microorganism is capable to oxidize organic pollutant into carbon dioxide and water.. Aerobic process implies high energy requirement, 0.7 – 1 kWh/kg COD, and low organic load rates, 0.5-2.0 kg COD/m3·d.

On the other hand, in anaerobic process, anaerobic microorganisms (specific to oxygen-free conditions) are selected for their ability to degrade organic matter present in wastewater. More precisely, organic pollutants are converted into biogas (methane + carbon dioxide) and a small amount of biosolids. In this wastewater systems, energy used could be reduced up to 10 times in comparation with aerobic process (0.07 – 1.0 kWh/k DQO) as aeration is not required. Moreover, biogas, methane-rich gas, may be used as renewable energy source, which reduces the energy demand of wastewater process.

Comparative balance of aerobic and anaerobic wastewater treatment processes

It is important to highlight that the organic load rates used in anaerobic process can reach up to 25 kg COD/m3·d, which allows the treatment of biodegradable wastewater with a high COD concentration, as well as reducing the reactor surface area.

Finally, anaerobic process also has the advantage of being able to value the granular biomass produced in the market, as sowing in reactors for the start-up of other plants, thus significantly reducing the cost associated with sludge treatment.

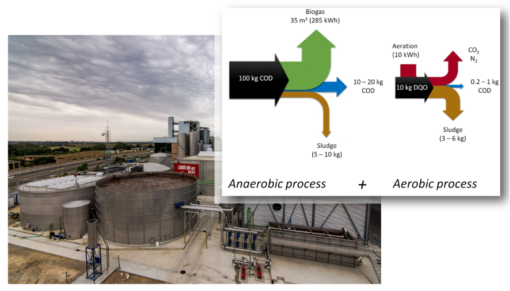

Synergistic binomial of biological processes: anaerobic + aerobic

Although anaerobic systems may be capable of treating wastewater with higher organic loads than aerobic ones, they have a limited capacity both for the removal of nutrients (ie, nitrogen and phosphorus) and for the refining of organic matter in the effluent (ie, COD removal yields <90%).

It is therefore evident that an effective and efficient treatment of industrial wastewater with a high biodegradable organic load with discharge into the water bodies should be carried out through the synergistic combination of the two biological processes:

- Anaerobic, as a roughing treatment and recovery of organic matter in an energy source such as biogas.

- Aerobic, as a process for polishing the COD and removing the nutrients to fulfillthe limits established in the wastewater discharge authorization.

Balance of the mixed wastewater treatment system: anaerobic + aerobic. Photo La Zaragozana (Ambar), success story of EDARi built and operated by AEMA

A case of success in the brewing sector for the treatment of wastewater using mixed anaerobic + aerobic technology is the Spanish brewery located in Zaragoza, La Zaragozana (Ambar). The WWTP of the aforementioned beverage company, built and operated by AEMA, is capable of treating 3,270 m3 of wastewater daily, producing about 5,000 m3 of biogas. The biogas is energetically valued in the facility itself, taking advantage of its calorific power, which contributes positively to the reduction of the brewery’s carbon footprint.

LIFE Multi-AD technology solution

The LIFE Multi-AD project is developing and industrializing an innovative technological solution based on the design of a high performance multi-stage anaerobic reactor patented by AEMA. The demonstration project will help as a technological lever to advance the synergistic combination of anaerobic and aerobic purification systems.

The LIFE Multi-AD project will reduce the environmental impact of food SMEs as well as the operating expenses derived from treatment. The technological solution will reduce the organic load of the wastewater, producing biogas, which will be used as a source of renewable energy, thus saving natural resources and reducing the carbon footprint.

The LIFE Multi-AD project is supported 60% by the LIFE + ENVIRONMENT program of the European Commission and is coordinated by AEMA, as an expert in industrial wastewater treatment technologies. Also involved in the consortium ITAINNOVA, technological center of reference in technological innovation, SIS, company that provides solutions in the field of industrial automation, EGA, specialist in the management and recovery of organic waste through anaerobic digestion and I&S, consultant and advisor in communication of European and international projects..